Z-type hoist

operational principle

When the multi-point feeding Z-type elevator is working, the deceleration motor drives two sprockets to move synchronously through bearings, so that the two chains that mesh with it move synchronously on the closed track. When the material is transported to the feeder, it slides into the horizontally forward hopper, and then the feeder's brush brushes the excess material from the hopper into the next hopper. As the material slides into the hopper and is not forcibly scraped, it will not cause the material to break. In this way, by synchronously moving the two chains, the hopper between the two chains can continuously move on its closed track. Under the action of the flipping wheel, the hopper flips, and the materials in the hopper fall into the temporary storage bin of the matching equipment through the discharge port of the elevator.

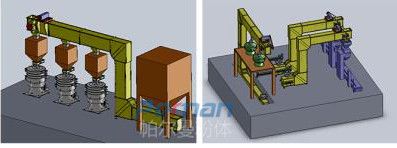

The multi-point feeding Z-type elevator has significant advantages such as large conveying capacity, high lifting height, stable and reliable operation, and long service life. This elevator is suitable for conveying powder, granular, and small pieces of materials with no grinding or low grinding properties. Currently, it is mainly used for feeding weighing and packaging machines, feeding and re feeding of color sorting machines, and three-dimensional cycle loading and unloading of automated production lines. The multi-point feeding Z-type elevator is divided into Z-type bucket elevator and C-type bucket elevator according to the different positions of the feeding and discharging ports. The C-type bucket elevator saves more space compared to the Z-type bucket elevator, and customers can choose according to the actual situation of the site.

Users can choose to configure

Chassis: Semi enclosed chassis - dustproof chassis - airtight chassis - stainless steel chassis - carbon steel spray painted chassis.

Hopper: stainless steel hopper - carbon steel hopper - food grade plastic hopper.

Drive: Explosion proof reducer, ordinary reducer.

Chain wheel: alloy steel chain wheel - stainless steel chain wheel.

Chain: Alloy steel chain - stainless steel chain.

Control: manual start stop, automatic start stop, variable frequency control, etc.

Other: The entire machine is explosion-proof, equipped with a forced ventilation system, an automatic hopper cleaning system, and an automatic refueling system.

Material of hopper:

Choose 1-ABS material

Choose 2-stainless steel 304 material

Choose 3-carbon steel material

Optional configuration

Case: Stainless steel case/carbon steel spray painted case

Hoppers: Food grade ABS hopper/Stainless steel hopper/Carbon steel hopper

Chain: Alloy steel chain/stainless steel chain

Sprocket: Alloy steel sprocket/stainless steel sprocket

Drive: ordinary motor/explosion-proof motor/variable frequency motor

Control: manual/automatic (customizable according to customer requirements)

The products are widely used in the pet food industry, puffed food industry, feed industry, candy industry, dried and fresh fruit industry, health food industry, grain precision processing industry, chemical and medical industry, hardware and electrical materials industry, military manufacturing industry, and so on. The main frame of the equipment can be made of materials such as carbon steel and 304 stainless steel according to different usage needs.